MWSS

Flexible coupling – Slit – type – Set screw type

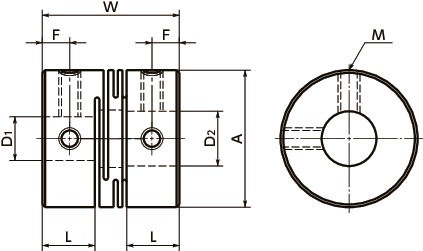

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | A | L | W | F | M | Wrench Torque (N・m) |

|---|---|---|---|---|---|---|

| MWSS-8 | 8 | 3.4 | 10 | 1.7 | M2 | 0.3 |

| MWSS-12 | 12 | 5.2 | 14 | 2.5 | M2.5 | 0.5 |

| MWSS-16 | 16 | 6.8 | 18 | 3 | M3 | 0.7 |

| MWSS-20 | 20 | 7.65 | 20 | 3 | M3 | 0.7 |

| MWSS-25 | 25 | 9.6 | 25 | 4 | M4 | 1.7 |

| MWSS-32 | 32 | 12.6 | 32 | 6 | M4 | 1.7 |

| Part Number | Max. Bore Diameter (mm) | Rated Torque* (N・m) | Max. Torque* (N・m) | Max. Rotational (min-1) | Static Torsional Stiffness (N・m/rad) | Max. Angular Misalignment (°) | Max. Axial Misalignment (mm) | Mass** (g) |

|---|---|---|---|---|---|---|---|---|

| MWSS-8 | 4 | 0.2 | 0.4 | 78000 | 49 | 1 | ±0.1 | 2.7 |

| MWSS-12 | 6 | 0.3 | 0.6 | 52000 | 140 | 1 | ±0.1 | 7.8 |

| MWSS-16 | 8 | 0.5 | 1 | 39000 | 240 | 1 | ±0.1 | 18 |

| MWSS-20 | 10 | 1 | 2 | 31000 | 330 | 1 | ±0.1 | 32 |

| MWSS-25 | 12 | 2 | 4 | 25000 | 720 | 1 | ±0.2 | 63 |

| MWSS-32 | 16 | 3.5 | 7 | 19000 | 1300 | 1 | ±0.2 | 130 |

*Adjustment of rated and maximum torque specifications for load fluctuations is not required.

For more detailed information, please refer to Selection Guidelines [PDF 171KB].

**Based on the maximum shaft bores.

| Part Number | Stock Bores D1-D2 | ||||

|---|---|---|---|---|---|

| MWSS-8 | 2-2 | 3-3 | |||

| MWSS-12 | 4-4 | 4-5 | 4.5-5 | 5-5 | |

| MWSS-16 | 5-5 | 5-6 | 6-6 | ||

| MWSS-20 | 5-6 | 5-8 | 6-6 | 6-8 | 8-8 |

| MWSS-25 | 5-6 | 6-6 | 6-8 | 8-8 | 8-10 |

| 10-10 | |||||

| MWSS-32 | 8-8 | 8-10 | 10-10 | 10-12 | 12-12 |

| 12-14 | |||||

●All products come with set screws.

●Recommended tolerance for shaft diameters is h6 and h7.

●Bore and keyway modifications are available on request. Please take advantage of our bore modification services.

For more information please refer to Custom Bore Modifications [PDF 495KB]

Material/Finish

| MWS/MWS-C | MWSS/MWSS-C | |

|---|---|---|

| Main body | A2017 Alumite Treatment | SUS303 |

| Hex Socket Set Screw |

SCM435 Ferrosoferric oxide film | SUSXM7 |

| Hex Socket Head Cap Screw |

SCM435 Ferrosoferric oxide film | SUSXM7 |

Structure

Set Screw type MWS,MWSS

MWS Made of aluminum alloy

MWSS Made of all stainless steel

Clamping type MWS-C,MWSS-C

MWS-C Made of aluminum alloy

MWSS-C Made of all stainless steel

Characteristics

- Applicable motors

MWS MWSS Servomotor – – Stepping motor ◎ ◎ General-purpose motor ◎ ◎ ◎: Excellent ○: Very good

- Property

MWS MWSS Zero Backlash ◎ ◎ High Torque ○ ○ High Torsional Stiffness ○ ○ Corrosion Resistance(All S.S.) – ◎ ◎: Excellent ○: Very good

- This is a metal spring coupling with single-piece construction. Slits are made into a cylindrical material.

- A plate spring formed by slits allows angular misalignment, and end-play to be accepted.

- There are two types of units made of aluminum alloy or all stainless steel.

Application

Transport device/XY stage/Parts feeder

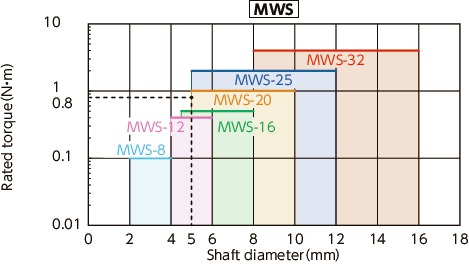

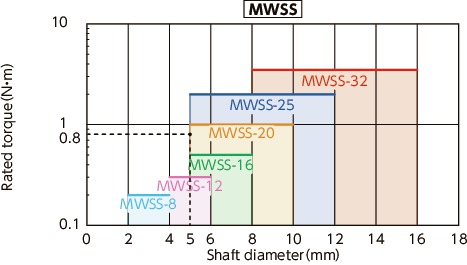

Selection

The area bounded by the shaft diameter and rated torque indicates is the selection size.

Selection example

In case of selected parameters of shaft diameter of φ 5 and load torque of 0.8 N•m, the selected size for MWS,MWSS is MWS-20,MWSS-20.

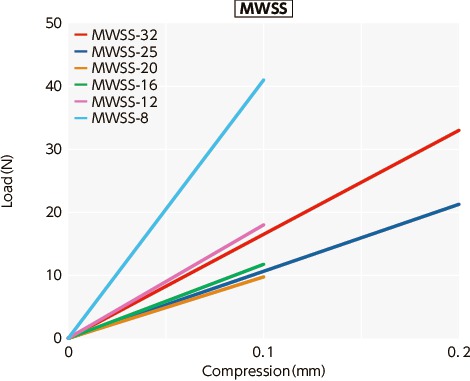

Thrust Reaction Force

Slip Torque

Concerning the sizes shown in the following table, please note that the shaft’s slip torque is smaller than the max. torque of MWS-C,MWSS-C .

| Part Number | Bore Diameter(mm) | |||||||

|---|---|---|---|---|---|---|---|---|

| 4 | 4.5 | 5 | 6 | 8 | 10 | 12 | 14 | |

| MWS-25C | 3 | 3.1 | 3.5 | |||||

| MWSS-12C | 0.3 | 0.4 | 0.5 | |||||

| MWSS-20C | 0.9 | 1.9 | ||||||

| MWSS-25C | 1.2 | 1.4 | 1.9 | 3.1 | ||||

| MWSS-32C | 1.9 | 2.4 | 3.4 | 4.1 | ||||

These are test values based on the condition of shaft’s dimensional allowance: h7, hardness: 34 – 40 HRC, and screw tightening torque of the values described in MWS-C,MWSS-C Dimension table.

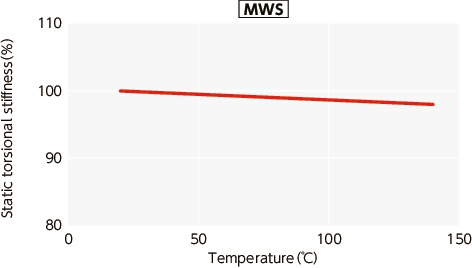

Change in static torsional stiffness due to temperature

This is a value under the condition where the static torsional stiffness at 20°C is 100%.

MWS,MWSS ’s change in torsional stiffness due to temperature is small and the change in responsiveness is extremely small. However, if the unit is used under higher temperature, be careful about misalignment due to elongation or deflection of the shaft associated with thermal expansion.