SPA-LC

Plastic screw – Hex Socket Low Head Bolt – RENY

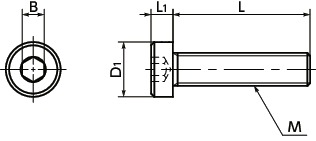

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | M | L | D1 | L1 | B | Tension Rupture Load(N)* | Torsional Torque (N・m)* | Qty per Pack | Mass (g) |

|---|---|---|---|---|---|---|---|---|---|

| SPA-M3-6-LC | M3 | 6 | 5.5 | 2 | 2 | 740 | 0.31 | 20 | 0.11 |

| SPA-M3-8-LC | M3 | 8 | 5.5 | 2 | 2 | 740 | 0.31 | 20 | 0.13 |

| SPA-M3-10-LC | M3 | 10 | 5.5 | 2 | 2 | 740 | 0.31 | 20 | 0.15 |

| SPA-M3-12-LC | M3 | 12 | 5.5 | 2 | 2 | 740 | 0.31 | 20 | 0.16 |

| SPA-M3-16-LC | M3 | 16 | 5.5 | 2 | 2 | 740 | 0.31 | 20 | 0.21 |

| SPA-M3-20-LC | M3 | 20 | 5.5 | 2 | 2 | 740 | 0.31 | 20 | 0.25 |

| SPA-M4-6-LC | M4 | 6 | 7 | 2.8 | 2.5 | 1325 | 0.62 | 20 | 0.24 |

| SPA-M4-8-LC | M4 | 8 | 7 | 2.8 | 2.5 | 1325 | 0.62 | 20 | 0.27 |

| SPA-M4-10-LC | M4 | 10 | 7 | 2.8 | 2.5 | 1325 | 0.62 | 20 | 0.31 |

| SPA-M4-12-LC | M4 | 12 | 7 | 2.8 | 2.5 | 1325 | 0.62 | 20 | 0.34 |

| SPA-M4-16-LC | M4 | 16 | 7 | 2.8 | 2.5 | 1325 | 0.62 | 20 | 0.4 |

| SPA-M4-20-LC | M4 | 20 | 7 | 2.8 | 2.5 | 1325 | 0.62 | 20 | 0.48 |

| SPA-M5-10-LC | M5 | 10 | 8.5 | 3.5 | 3 | 2050 | 1.2 | 20 | 0.43 |

| SPA-M5-12-LC | M5 | 12 | 8.5 | 3.5 | 3 | 2050 | 1.2 | 20 | 0.48 |

| SPA-M5-16-LC | M5 | 16 | 8.5 | 3.5 | 3 | 2050 | 1.2 | 20 | 0.59 |

| SPA-M5-20-LC | M5 | 20 | 8.5 | 3.5 | 3 | 2050 | 1.2 | 20 | 0.71 |

| SPA-M5-25-LC | M5 | 25 | 8.5 | 3.5 | 3 | 2050 | 1.2 | 20 | 0.87 |

| SPA-M5-30-LC | M5 | 30 | 8.5 | 3.5 | 3 | 2050 | 1.2 | 20 | 1 |

| SPA-M6-16-LC | M6 | 16 | 10 | 4 | 4 | 2798 | 2.15 | 20 | 0.96 |

| SPA-M6-20-LC | M6 | 20 | 10 | 4 | 4 | 2798 | 2.15 | 20 | 1.1 |

| SPA-M6-25-LC | M6 | 25 | 10 | 4 | 4 | 2798 | 2.15 | 20 | 1.3 |

| SPA-M6-30-LC | M6 | 30 | 10 | 4 | 4 | 2798 | 2.15 | 20 | 1.5 |

| SPA-M6-40-LC | M6 | 40 | 10 | 4 | 4 | 2798 | 2.15 | 20 | 2.1 |

* The values in the table are reference values and are not guaranteed values. The recommended tightening torque is 50% of the twisting rupture torque.

Material/Finish

| SPA-LC | |

|---|---|

| Main body | RENY* (Glass Fiber 50% Reinforced Polyamide MXD6) (Black) |

| Heat resistance temperature** | 105℃ |

*RENY is a registered trademark of Mitsubishi Engineering-Plastics Corporation.

**A value of plastic materials. The allowable operating temperature of the product varies depending on use conditions such as tightening torque.

Application

Heat insulation and dew condensation prevention of electric and

electronic devices / refrigerating and freezing facilities /

Weight saving of offshore instruments, plating facility and

automobile, aircraft and space equipment, etc.

Characteristics

- Hex socket head cap screw with low head.

- For space-saving of equipment/device and applications with a limited top space.

- RENY is thermoplastic engineering plastics with excellent tensile strength and bending strength.

- It is highly fatigue-resistant and has excellent creeping and heat insulation properties.

- While it is nearly as strong as metal, its weight is approximately 1/5 of iron.

- Plastic screw properties and precautions for use