SNSTG

Socket Head Cap Screws – High Intensity Titanium Alloy

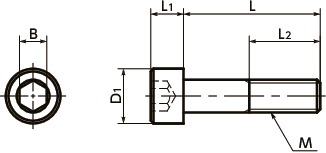

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | M | L | D1 | L1 | B | L2 | Tension Rupture Load (N)* | Qty per Pack | Mass (g) |

|---|---|---|---|---|---|---|---|---|---|

| SNSTG-M3-6 | 3 | 6 | 5.5 | 3 | 2.5 | Full Thread | 5240 | 1 | 0.4 |

| SNSTG-M3-8 | 3 | 8 | 5.5 | 3 | 2.5 | Full Thread | 5240 | 1 | 0.45 |

| SNSTG-M3-10 | 3 | 10 | 5.5 | 3 | 2.5 | Full Thread | 5240 | 1 | 0.5 |

| SNSTG-M3-12 | 3 | 12 | 5.5 | 3 | 2.5 | Full Thread | 5240 | 1 | 0.55 |

| SNSTG-M3-16 | 3 | 16 | 5.5 | 3 | 2.5 | Full Thread | 5240 | 1 | 0.66 |

| SNSTG-M3-20 | 3 | 20 | 5.5 | 3 | 2.5 | Full Thread | 5240 | 1 | 0.77 |

| SNSTG-M4-8 | 4 | 8 | 7 | 4 | 3 | Full Thread | 8850 | 1 | 0.94 |

| SNSTG-M4-10 | 4 | 10 | 7 | 4 | 3 | Full Thread | 8850 | 1 | 1 |

| SNSTG-M4-12 | 4 | 12 | 7 | 4 | 3 | Full Thread | 8850 | 1 | 1.1 |

| SNSTG-M4-16 | 4 | 16 | 7 | 4 | 3 | Full Thread | 8850 | 1 | 1.3 |

| SNSTG-M4-20 | 4 | 20 | 7 | 4 | 3 | Full Thread | 8850 | 1 | 1.5 |

| SNSTG-M4-25 | 4 | 25 | 7 | 4 | 3 | Full Thread | 8850 | 1 | 1.8 |

| SNSTG-M4-30 | 4 | 30 | 7 | 4 | 3 | Full Thread | 8850 | 1 | 2.1 |

| SNSTG-M5-10 | 5 | 10 | 8.5 | 5 | 4 | Full Thread | 14700 | 1 | 1.5 |

| SNSTG-M5-12 | 5 | 12 | 8.5 | 5 | 4 | Full Thread | 14700 | 1 | 1.7 |

| SNSTG-M5-16 | 5 | 16 | 8.5 | 5 | 4 | Full Thread | 14700 | 1 | 2 |

| SNSTG-M5-20 | 5 | 20 | 8.5 | 5 | 4 | Full Thread | 14700 | 1 | 2.3 |

| SNSTG-M5-25 | 5 | 25 | 8.5 | 5 | 4 | Full Thread | 14700 | 1 | 2.7 |

| SNSTG-M5-30 | 5 | 30 | 8.5 | 5 | 4 | Full Thread | 14700 | 1 | 3.2 |

| SNSTG-M5-35 | 5 | 35 | 8.5 | 5 | 4 | Full Thread | 14700 | 1 | 3.6 |

| SNSTG-M6-10 | 6 | 10 | 10 | 6 | 5 | Full Thread | 20800 | 1 | 2.7 |

| SNSTG-M6-12 | 6 | 12 | 10 | 6 | 5 | Full Thread | 20800 | 1 | 2.9 |

| SNSTG-M6-16 | 6 | 16 | 10 | 6 | 5 | Full Thread | 20800 | 1 | 3.3 |

| SNSTG-M6-20 | 6 | 20 | 10 | 6 | 5 | Full Thread | 20800 | 1 | 3.7 |

| SNSTG-M6-25 | 6 | 25 | 10 | 6 | 5 | Full Thread | 20800 | 1 | 4.3 |

| SNSTG-M6-30 | 6 | 30 | 10 | 6 | 5 | Full Thread | 20800 | 1 | 4.7 |

| SNSTG-M6-35 | 6 | 35 | 10 | 6 | 5 | Full Thread | 20800 | 1 | 5.6 |

| SNSTG-M6-40 | 6 | 40 | 10 | 6 | 5 | Full Thread | 20800 | 1 | 6.2 |

| SNSTG-M6-45 | 6 | 45 | 10 | 6 | 5 | Full Thread | 20800 | 1 | 6.9 |

| SNSTG-M6-50 | 6 | 50 | 10 | 6 | 5 | 45 | 20800 | 1 | 7.5 |

| SNSTG-M8-16 | 8 | 16 | 13 | 8 | 6 | Full Thread | 33700 | 1 | 6.9 |

| SNSTG-M8-20 | 8 | 20 | 13 | 8 | 6 | Full Thread | 33700 | 1 | 7.6 |

| SNSTG-M8-25 | 8 | 25 | 13 | 8 | 6 | Full Thread | 33700 | 1 | 8.5 |

| SNSTG-M8-30 | 8 | 30 | 13 | 8 | 6 | Full Thread | 33700 | 1 | 9.6 |

| SNSTG-M8-35 | 8 | 35 | 13 | 8 | 6 | Full Thread | 33700 | 1 | 11 |

| SNSTG-M8-40 | 8 | 40 | 13 | 8 | 6 | Full Thread | 33700 | 1 | 12 |

| SNSTG-M8-45 | 8 | 45 | 13 | 8 | 6 | Full Thread | 33700 | 1 | 13 |

| SNSTG-M8-50 | 8 | 50 | 13 | 8 | 6 | 45 | 33700 | 1 | 14 |

| SNSTG-M10-16 | 10 | 16 | 16 | 10 | 8 | Full Thread | 58900 | 1 | 12 |

| SNSTG-M10-20 | 10 | 20 | 16 | 10 | 8 | Full Thread | 58900 | 1 | 13 |

| SNSTG-M10-25 | 10 | 25 | 16 | 10 | 8 | Full Thread | 58900 | 1 | 14 |

| SNSTG-M10-30 | 10 | 30 | 16 | 10 | 8 | Full Thread | 58900 | 1 | 16 |

| SNSTG-M10-35 | 10 | 35 | 16 | 10 | 8 | Full Thread | 58900 | 1 | 17 |

| SNSTG-M10-40 | 10 | 40 | 16 | 10 | 8 | Full Thread | 58900 | 1 | 19 |

| SNSTG-M10-45 | 10 | 45 | 16 | 10 | 8 | Full Thread | 58900 | 1 | 21 |

| SNSTG-M10-50 | 10 | 50 | 16 | 10 | 8 | 45 | 58900 | 1 | 22 |

*Values in chart are for reference only. They are not guaranteed values.

Material/Finish

| SNSTG | |

|---|---|

| Main Body | Ti-6Al-4V(64 Titanium) |

Application

Lightweight applications in automobiles, aircrafts, spacecrafts, and robots

FPD production equipment, semiconductor devices, electrical and

electronic equipment, and aquatic applications

Characteristics

- Screws made of high strength titanium alloy.

- Specific gravity is approximately by 60% of stainless steel.

- Nonmagnetic.

- Screws with resistance to corrosion and particularly strong against seawater.

- Chemical polishing and brightening processing improve the screw surface. Furthermore, the screws are cleanroom washed, cleanroom packed, and comply with clean specifications that require no oil or foreign matter deposits.

- About the properties of titanium⇒Properties of Titanium

Physical property

| Ti-6Al-4V(64 Titanium) | |

|---|---|

| Specific Gravity | 4.43 |

| Melting Point(℃) | 1540 |

| Longitudinal Elastic Modulus(GPa) | 113 |

| Thermal Conductivity(W/(m・k)) | 7.5 |

| Linear Expansion Coefficient(K-1) | 8.8×10-6 |

| Electric Resistance(μΩ・m) | 1.7 |

| Amplitude Permeability(μ) | 1.0002(Nonmagnetic) |

Values in chart are for reference only. They are not guaranteed values.

Mechanical property

| Ti-6Al-4V(64 Titanium) | |

|---|---|

| Tensile Strength(N/mm2) | 895 or Higher |

| 0.2% Proof Stress(N/mm2) | 825 or Higher |

| Elongation(%) | 10 or Higher |

Values in chart are for reference only. They are not guaranteed values.