For clean room

Precisely because the products that are used in a special environment of clean room, safety and accuracy is required.

Therefore introduced advanced washing machines and measurement equipment is available in Furibea, perform various tests on the performance and durability. We ensure the product development to realize the long-term safe and reliable transport.

Implement the assumed test a variety of conditions

So that you longer safe use, assuming a variety of conditions, we conduct the test.

Withstand use under any environment, we strive to constantly improve the quality to keep the high strength and accuracy.

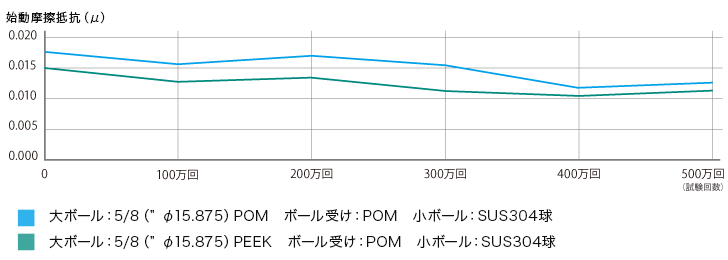

Furibea endurance test for clean rooms

[Test conditions]

① applied load: 500 gf

② operation pattern: stroke 15mm (15mm / sec round trip 30Mm / 3Sec)

③ Number of tests: 500 million times (measured in 500,000 times / each)

Furibea for the cleanroom, manufacturing consistently in a clean room facility in the plant until the packing from the assembly.

The high quality of the product, it is possible to supply stable.

The precision cleaning course, also available to the cleanliness of your request.

Wide range of products group and the fine-grained correspondence, and meet in a variety of applications.

Degreasing and precision cleaning and assembly flow chart

Clean Booth cleaning chamber (ultrasonic washing machine, vacuum dryer)

Degreasing and precision cleaning in a clean booth, to pursue the combined cleanliness to customer requirements, implementation.

※ corresponds to the VOC regulations and standards.

Clean room

Achieve an in-house integrated production system to the packaging from the manufacturing / assembly in a clean room facility.

Features of Material

| Material name | Wear resistance | Chemical resistance(alkaline) | Chemical resistance(acidic) | Chemical resistance(alcohol) | Water absorption | ※ heat temperature(reference value) | The specific volume resistance Ω · cm |

|---|---|---|---|---|---|---|---|

| Polyacetal (POM) | ○ | ○ | ▲ | ○ | 0.22 | 90 ℃ | > 10 14 |

| Ultra-high molecular weight polyethylene (UHMWPE) | ◎ | ○ | ▲ | ○ | <0.01 | 80 ℃ | > 1013 |

| Polytetrafluoroethylene(PTFE) | ▲ | ○ | ○ | ○ | 0.03 | 260 ℃ | 1010~10 12 |

| Polyetheretherketone (PEEK) | ○ | ◎ | ▲ | ◎ | 0.04 | 240 ℃ | 1016 |

| Polyamide-imide (PAI) | ◎ | ○ | ○ | ○ | 0.33 | 250 ℃ | 1017 |

| UPE / conductive grade | ◎ | ○ | ▲ | ○ | Over | 80 ℃ | 104 |

| PEEK / conductive grade | ○ | ◎ | ▲ | ◎ | Over | 240 ℃ | 105~106 |

※ heat temperature is a reference value of the material itself. Different temperature setting, depending on the operational conditions of Furibea product.

① The product for the clean room, the grease is not applied. Separately, it can also coating of low dust generation grease. Please contact the manufacturer, part number, or the like.

② cleanliness C100 ~ C1,000 (C100 standard correspondence. Or less, please contact our representative.) *

Cleanliness in the environment in a clean room, products are means that have been produced in the.

③ cleaning flow chart described. Please contact us for ④ other material.

Rich product variations to choose

Able choose depending on the purpose and use, the environment and conditions,

offers a wealth of product variations.

Single item as well, it is also possible to combine more than one product.