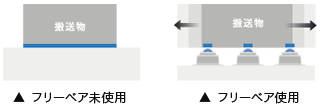

Furibea

In the case of the roller conveyor, it can not be only linearly moving the work, but if Furibea to use the ball, it is possible to move to the 360 ° direction.

② low start-up friction resistance value

Because according to the transported material friction in that you use the Furibea is changed to the “rolling friction” from “sliding friction”, it becomes possible to move lightly the transported material. (Start-up frictional resistance value: When you move heavy objects, it refers to the very first of the resistance value when the start moving from stop to that state.)

Structure of Furibea

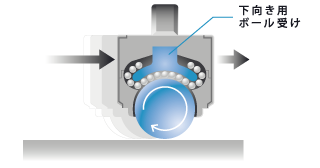

① upward for-down for Furibea

※ for your use in the oblique and sideways inquiry please.

He received the ball is a small ball go into, and rotate the ball carrying a large ball on it.

For the down inside the ball receiving By attaching the, it has been designed so that small ball is circulated.

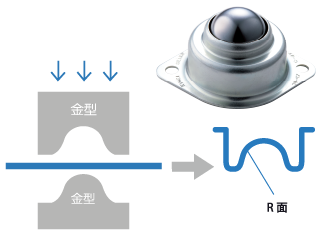

Ball received the press molded product (multiplied by the pressure in the mold, processing method will be molded from a metal plate or the like) made from ⇒ plate.

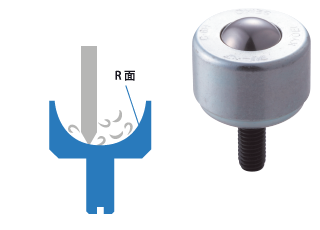

Ball received is cutting (by cutting the material with a knife, processing methods continue to shape the form) has been product ⇒ make by cutting a round bar.

② press-molded product , cutting processed goods

From the above content, the thickness of the R-plane is pressed product is thin, cutting goods are made thicker.

※ transport products alone weight of the press-molded product, please not exceed 500kg.

Allowable load of Furibea

The allowable load of Furibea, SS 4 0 0 equivalent of rigid body to transport products (surface that comes into contact with the Furibea was polished green lumber) when you use, start-up friction resistance (μ) is to maintain the 3/10 less than or equal to 0 it is the largest of the load applied to the Furibea alone capable of.

※ There is a case of unbalanced load by the shape of the conveyed object as shown in the figure on the right is generated, it is assumed that the load applied to such cases all of Furibea is equal to or less than the allowable load.

Please set the mounting pitch in consideration of the weight and size of the transported material.

There is a tolerance even in the height of Furibea, also and the table surface of Furibea mounting, conveying surface is also not a flat. Not applied evenly load in all Furibea attached Therefore, unbalanced load only in a certain part might take. More than the permissible load in this case is applied to the Furibea, it will adversely affect the starting resistance and life.

For this reason,

cutting processed goods ● = acceptable load 2 × / 3

● press molded products = allowable load × 1/2

Please choose the mounting so as to be about load pitch.

However, Furibea containing the spring, Furibea who received the unbalanced load is pushed down, it has been taken into account so that more of Furibea come into contact with each other, this does not apply.

Please note on the material of the transported material

Table Ⅰ is the result of the measurement in our test machine “start-up friction resistance (μ)” for the allowable load of each Furibea. In the test machine, the contact surface between the ball, we use the hardening polishing the steel (SK3, HRC60 or more).

Table Ⅰ

| C-6H | C-8H | C-12H | C-8Y | C-12K | |

|---|---|---|---|---|---|

| Test load (allowable load) | 50kg | 80kg | 200kg | 30kg | 60kg |

| Start-up friction resistance (μ) | 0.013 | 0.011 | 0.012 | 0.015 | 0.013 |

We measured the difference between the starting resistance value due to the material of the surface in contact with the ball. As can be seen from Table Ⅱ, SS 4 0 0 is starting frictional resistance (μ) is increased more than twice compared to SK 3, also who will be more significant in the black leather material compared to the abrasive even with the same SS material . Therefore, in order to move lightly the heavy even a little, please be something smooth stiffen the bottom of the transported material.

Table Ⅱ

C-8H (allowable load 80kg)

| Material | |||

|---|---|---|---|

| SK3HRc60 more contact surface polishing | SS400 contact surface polishing | SS400 black leather | |

| Load 80kg | 0.92kg (μ = 0.011) | 2.02kg (μ = 0.025) | 2.22kg (μ = 0.028) |

Table Ⅲ As described, in the case surface in contact with the ball of wood, generally becomes μ = 0.09 ~ 0.1, will be about three times a little compared to the SS400 black leather material. Therefore, take a lot of as much as possible contact in the case of wood, and used to disperse the load, please use to attach the iron plate on the bottom surface of the carrier material in order to further conveyed lightly.

Table Ⅲ

C-8Y (allowable load 30kg)

| Material wood (pine) | |

|---|---|

| Load 30kg | 2.7kg (μ = 0.09) |

C-12K (allowable load 60kg)

| Material wood (pine) | |

|---|---|

| Load 60kg | 5.4kg (μ = 0.09) |

Also available design and development of custom-made

What you want your in Furibea, want shape, size you want, according to the want applications, also supports a complete made-to-order. Please do not hesitate to contact us.