TSUBAKI Sprockets for Top Chains

Sprockets for BT6 Chain

Solid sprockets for BT6 plastic modular chain.

BT6 sprockets are made to fit loosely on the shaft to absorb differences in thermal expansion between the chain and conveyor, and alignment errors between the sprockets and chain.

- Available with 10T and 24T.

- BT6 sprockets have an alignment mark for phase matching.

Line-up

| Type | Solid Sprockets | |

|---|---|---|

| Basic model no. | BT6-10T | BT6-24T |

| Applicable chains | BTC6, BTCP6, BTC6-T, BTO6, BTN6 | |

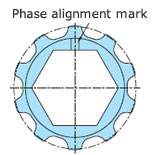

| Shape | *Sample hexagonal shape

|

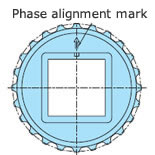

*Sample square shape

|

| Material | Sprockets for LFB, MWS, ULF, DIA, and DIY Series: Reinforced polyamide Sprockets for KV150 and 250 Series: Special engineering plastic |

|

| No. of teeth | 10 | 24 |

| Bore shape | Hexagonal/Square | |

| Features |

|

|

- The number of BT6 sprockets installed, and positions where BT6 sprockets are installed, will vary depending on load conditions.

- Made-to-order product.

Reference Number System

| BT6 | – | 10T | – | 38 | H |

| (1) | (2) | (3) | (4) |

(1) Chain type: BT6 chain

(2) No. of teeth: 10T = 10, 24T = 24

(3) Bore diameter: mm

(4) Bore shape: H = Hexagonal, S = Square