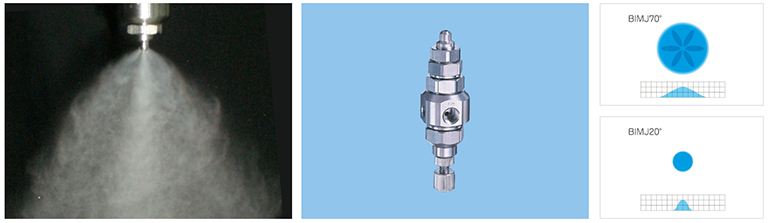

IKEUCHI BIMJ series nozzles

Small Capacity Fine Fog Nozzles/ Full Cone Spray

| Thread standard | – | Pipe conn. size | – |

|---|---|---|---|

| Standard pressure | – | Spray angle | 20 – 70°(*1) |

| Spray capacity | 1.3 – 107 ℓ/hr, Normal | Supply air type | Compressed air |

| Liquid feeding system | Liquid pressure | Mean droplet diameter | 20 – 100 μm |

| Air consumption | 25 – 103N ℓ/min | Air pressure | 0.2 – 0.4 MPa |

| Free passage diameter | 0.4 – 3.1 mm(*2) |

Features

Full cone spray pneumatic nozzle producing fine atomization with a mean droplet diameter of 100μm or less (*3).

Features large turn-down ratio under liquid pressures of 0.1-0.3 MPa.

Available in spray angles of 20゚ and 70゚.

*1) Spray angle measured at compressed air pressure of 0.3 MPa and liquid pressure of 0.1 MPa.

*2) Free passage diameter of spray orifice.

*3) Measured by Laser Doppler Method.

Applications

Spraying: Mold release agent, lubricant, deodorant (trash pit, refuse collector, inlet conduit), oil, surface treatment agent, rust preventive, honey, insecticide, aqueous urea, etc.

Cooling: Dies, gas, glass, steel plates, steel pieces, moldings, automobile bodies, plastic products, etc.

Moisture control: Paper, gas, ceramics, concrete, etc.

Steelmaking industry

Raw material process: Dust suppression at the conveyer line, Flue gas denitration reducing agent.

Steelmaking process: Cooling refractories at maintenance of ladle and tundish, Cooling electric furnace and electrode.

Rolling mill process: Cooling coil

Surface finish process: Minimized spangle treatment at the continuous galvazing line, Cooling coating line.

Industries in which this nozzle is used

Steelmaking, Pollution control, Electronics, Paper & pulp, Printing, Food, Automotives

Product specifications

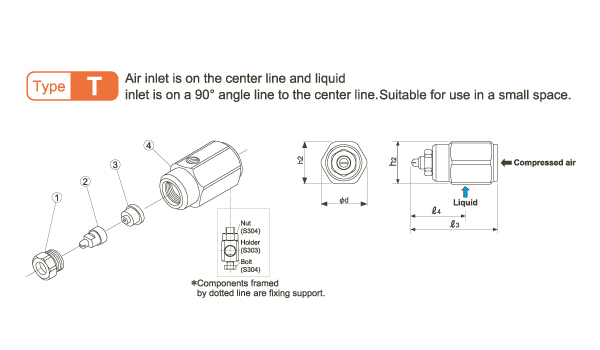

| Structure | • Comprising 4 parts : Spray tip, core, cap and adaptor. • Connecting adaptors are available from 8 types (N, T, ND, SP, SN and ball joint type of UND, USP, USN). • Internal mixing type designed to mix compressed air and liquid inside the nozzle (Inner air type : compressed air flows in the center of the nozzle, while liquid flows along its circumference). • Liquid pressure type. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | • S303 • [Optional material] S316L |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

| Mass |

Details of adaptors are shown on the catalog. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ourter dimension |

①cap Dimensions

*1) Excludes BIMJ2004. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||