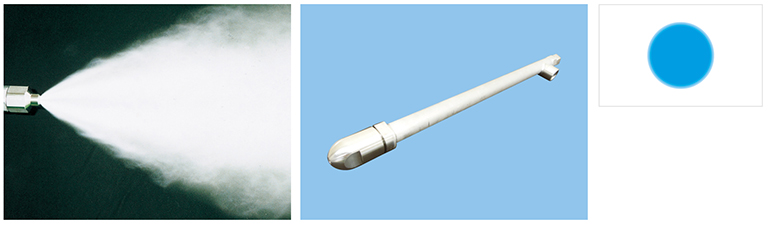

IKEUCHI GSIM II series nozzles

Large Capacity Fine Fog Nozzles/ Full Cone Spray

| Thread standard | – | Pipe conn. size | 1*1/4T10 – 2T10 |

|---|---|---|---|

| Standard pressure | – | Spray angle | 20 – 60° |

| Spray capacity | 70 – 1,600 ℓ/hr(*1) | Supply air type | Compressed air |

| Liquid feeding system | Liquid pressure | Mean droplet diameter | – |

| Air consumption | 340 – 5,800N ℓ/min(*2) | Air pressure | – |

| Free passage diameter | 1.8 – 4.0 mm(*3) |

Features

• Full cone pneumatic spray nozzle producing large amount of “fine fog”.

• Energy-saving design – mean droplet diameter of 50 μm and a maximum droplet diameter of 150 μm (*4) at an air-water ratio of 130.

• Large turn-down ratio.

• Spray angle is 20゚ and 60゚.

*1) Measured at compressed air pressure of 0.3 MPa and liquid pressure of 0.2-0.5 MPa.

*2) Measured at compressed air pressure of 0.3-0.4 MPa.

*3) Free passage diameter of liquid inlet for GSIMⅡ60゚ spray angle type.

*4) Measured by Laser Doppler Method.

Applications

Cooling: Gas, moldings, refractories

Moisture control: Gas, concrete

Combustion: Oil, waste fluid

Dust suppression: Recycling facilities, material facilities, moldings

Steelmaking industry

Iron making process: Cooling flue gas before gas turbine, Cooling refractories at maintenance, Dust suppression at casting of pig iron

Steel making process: Cooling converter shell at maintenance, Flue gas cooling on electric furnace, Dust suppression at casting of steel

Rolling mill and surface finish process: Cooling flue gas from heating furnace, Dust suppression on rolling mill outlet

*1) Measured by Laser Doppler Method

Industries in which this nozzle is used

Steelmaking, Pollution control

Product specifications

| Structure | • Comprising several parts : Spray tip, whirler, adaptor, outer pipe (for air), inner pipe (for liquid), etc. • Internal mixing type designed to mix compressed air and liquid inside the nozzle (Outer air type : Liquid flows in the center of the nozzle, while compressed air flows along its circumference). • Liquid pressure type. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | • Nozzle tip, nozzle core, nozzle adaptor, outer pipe (for air): S316L • Inner pipe (for liquid), joint, socket, bolt: S304 • Whirler: S316L equivalent • O-ring: FKM • Packing: Metal wire reinforced AES wool • Flange: SCS13(S304) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Mass | Mass

Nozzle length

・L1 shows the standard length |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Outer dimensions |

Dimensions and Pipe connection sizes

Appearance and dimensions may differ depending on nozzle codes and materials. Please contact us for details. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||