IKEUCHI DDA series nozzles

Oval Spray Semi-Fine Fog Nozzles

| Thread standard | – | Pipe conn. size | 1/4 – 1/2F |

|---|---|---|---|

| Standard pressure | – | Spray angle | 75° – 125°(*1) |

| Spray capacity | 0.14 – 57.3 ℓ/hr, Normal | Supply air type | Compressed air |

| Liquid feeding system | Liquid pressure | Mean droplet diameter | 15 – 200 μm |

| Air consumption | 49 – 190N ℓ/min | Air pressure | 0.1 – 0.4 MPa |

| Free passage diameter | 2.4 – 4.0 mm(*2) |

Features

• Oval spray pneumatic nozzle producing a large volume of semi-fine atomization with a mean droplet diameter of 50 μm or more (*3).

• Liquid pressure type under the liquid pressures of 0.07-0.7 MPa.

• Large turn-down ratio with minimal variation in spray angle.

• Uniform distribution suitable for multiple-nozzle arrangements.

• Oval spray pattern covers wide area.

• Large free passage diameter minimizes clogging.

• Spray angle is 75゚, 80゚, 100゚, and 125゚.

*1) Measurement standard for spray angle varies depending on nozzle code.

*2) Free passage diameter of spray orifice.

*3) Measured by Laser Doppler Method.

Applications

Cooling: Gas, steel plates, steel pieces, pipes, moldings, etc.

Moisture control: Gas

Combustion: Factory effluents and waste water

[Steelmaking industry]

Steel making process: Cooling continuous casted steel (bloom, slab short side, billet), cooling roll of casting machine

Rolling mill process: Cooling steel plate on continuous annealing line, roll in heat treatment, and magnetic steel

Industries in which this nozzle is used

Steelmaking, Pollution Control

Product specifications

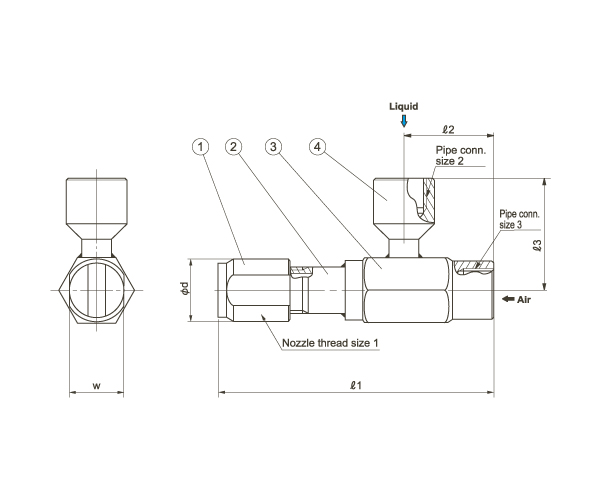

| Structure | • Comprising 4 parts : Nozzle body, pipe, mixing adaptor, liquid nipple. • Internal mixing type designed to mix compressed air and liquid inside the nozzle (Pre-mix type : compressed air and liquid are already mixied inside the nozzle adaptor). • Liquid pressure type. |

||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | • Nozzle body: S303 • Others: S304 |

||||||||||||||||||||||||||||||||||||||||||||||||||

| Mass |

・ L1 shows the standard length which is shortest, and the longest length is 1500 mm. |

||||||||||||||||||||||||||||||||||||||||||||||||||

| Outer dimensions |

①Nozzle body • Appearance and dimensions may differ depending on nozzle codes and materials. Please contact us for details. |

||||||||||||||||||||||||||||||||||||||||||||||||||