IKEUCHI BIMV series nozzles

Small Capacity Fine Fog Nozzles/ Flat Spray

| Thread standard | – | Pipe conn. size | – |

|---|---|---|---|

| Standard pressure | – | Spray angle | 45° – 110°(*1) |

| Spray capacity | 1.0 – 107 ℓ/hr, Normal | Supply air type | Compressed air |

| Liquid feeding system | Liquid pressure | Mean droplet diameter | 20 – 100 μm |

| Air consumption | 20 – 103N ℓ/min | Air pressure | 0.2 – 0.4 MPa |

| Free passage diameter | 0.2 – 1.6 mm(*2) |

Features

- Flat spray pneumatic nozzle producing fine atomization with a mean droplet diameter of 100 μm or less (*3).

- Features large turn-down ratio under liquid pressures of 0.1-0.3 MPa.

- Produces two different spray distributions; uniform spray distribution throughout spray pattern area (when spraying at a low air-water ratio), and a mountain-shaped distribution having gradually tapered edges (at a high air-water ratio).

- Three spray angles of 110゚, 80゚, and 45゚ are available.

1) Spray angle measured at compressed air pressure of 0.3 MPa and liquid pressure of 0.1 MPa.

2) Free passage diameter of spray orifice.

3) Measured by Laser Doppler Method.

Applications

Spraying: Mold release agent, lubricant, deodorant (trash pit, refuse collector, inlet conduit), oil, surface treatment agent, rust preventive, honey, insecticide, aqueous urea, etc.

Cooling: Dies, gas, glass, steel plates, steel pieces, moldings, automobile bodies, plastic products, etc.

Moisture control: Paper, gas, ceramics, concrete, etc.

Cleaning: Printed circuit boards, glass tubes, etc.

Others: Dust suppression, Catalyst denitration, etc.

Steelmaking industry

Raw material process: Dust suppression at the conveyer line, Flue gas denitration reducing agent.

Steelmaking process: Cooling refractories at maintenance of ladle and tundish, Cooling electric furnace and electrode.

Rolling mill process: Cooling coil

Surface finish process: Minimized spangle treatment at the continuous galvazing line, Cooling coating line.

Industries in which this nozzle is used

Steelmaking, Pollution control, Electronics, Paper & pulp, Printing, Food, Automotives

Product specifications

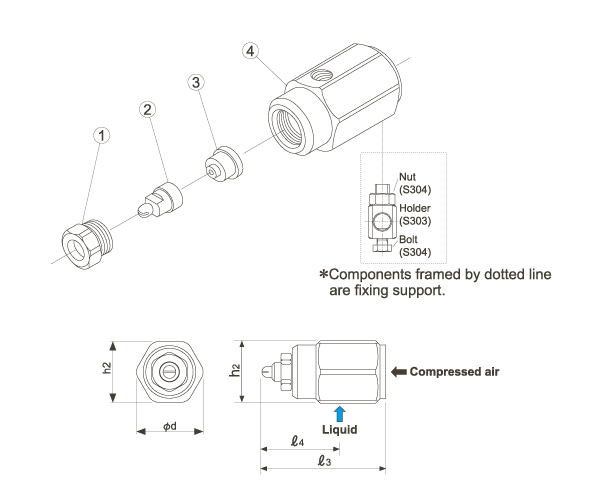

| Structure | • Comprising 4 parts : Spray tip, core, cap and adaptor. • Connecting adaptors are available from 8 types (N, T, ND, SP, SN and ball joint type of UND, USP, USN). • Internal mixing type designed to mix compressed air and liquid inside the nozzle (Inner air type : compressed air flows in the center of the nozzle, while liquid flows along its circumference). • Liquid pressure type. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | • S303 or PP • [Optional material] S316L |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

| Mass |

Details of adaptors are shown on the catalog. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ourter dimension |

①cap Dimensions

Appearance and dimensions may differ depending on nozzle codes and materials. Please contact us for details. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||