Webstar

TK WEBSTAR is a high-performance web guide system backed by the know-how and refined technology of Toyo Machinery, a manufacture specialized in web guide over half a century.

This system fully shows its excellent web guide function as combined with TK position controller and sensor.

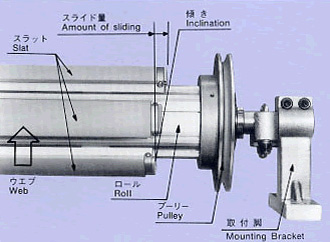

Webstar corrects the zig-zag movement of the web by moving the slats around the roll to right and left. It can be simply installed at the corner of process line for space saving and tension adjustment on the web is possible by means of synchronization with main body. And a webstar equipped with DC Brushless motor is also available.

WEBSTAR WB-210 / WB-220 / WB-300

Make corrections serpentine slat is attached to the roll surface is moved parallel to the left or right. Does not take place can be mounted easily in the corner of the line. You can also adjust the tension applied to the web by taking the tuning of the mechanical drive.

- slats that are attached to the roll surface, will slide by a command from the sensor. The slide and tilt of the slats this amount, will guide you through the web.

- on the surface of the slat is using the rubber, less slip, will guide you exactly quick.

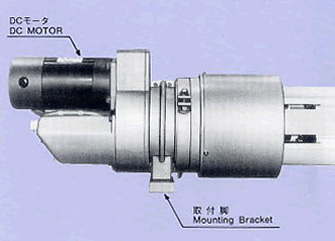

Rubber materials: thermoplastic elastomer (TPE), the other silicon - In the slide mechanism is adopted in DC servo motor and ball screw high performance. To achieve high accuracy and long life.

- role is brought around and the web, if you need tuning can be equipped with a pulley drive (optional). It is also possible due to inverter motor tuning system (optional).

Technical Data

| MODEL | Roll surface length |

Roll diameter | Number of slats | The maximum slope |

Maximum amount of slide |

Maximum slide speed |

|---|---|---|---|---|---|---|

| WB-210 | ~ 2400mm | φ164 | 6 | ± 7 ° | ± 35mm | 80mm/sec |

| WB-220 | ~ 3200mm | φ190 | 8 | ± 7 ° | ± 35mm | 95mm/sec |

| WB-300 | ~ 4500mm | φ240 | 10 | ± 7.5 ° | ± 55mm | 70mm/sec |

Application Examples

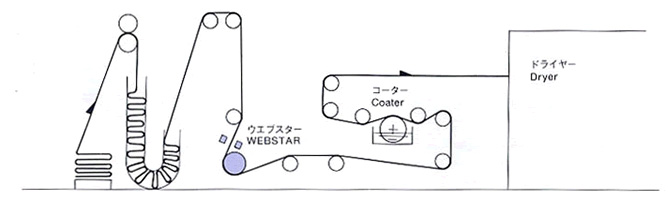

Non-woven Slitting

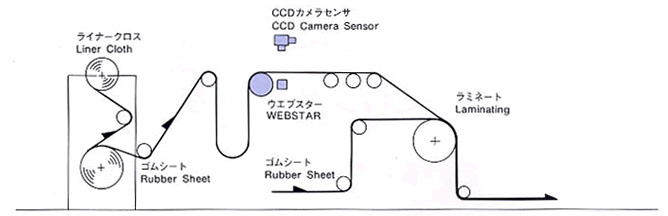

Rubber Sheet Laminating

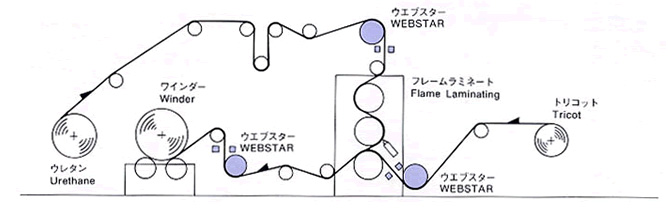

Urethane Flame Laminating

Carpet Coating